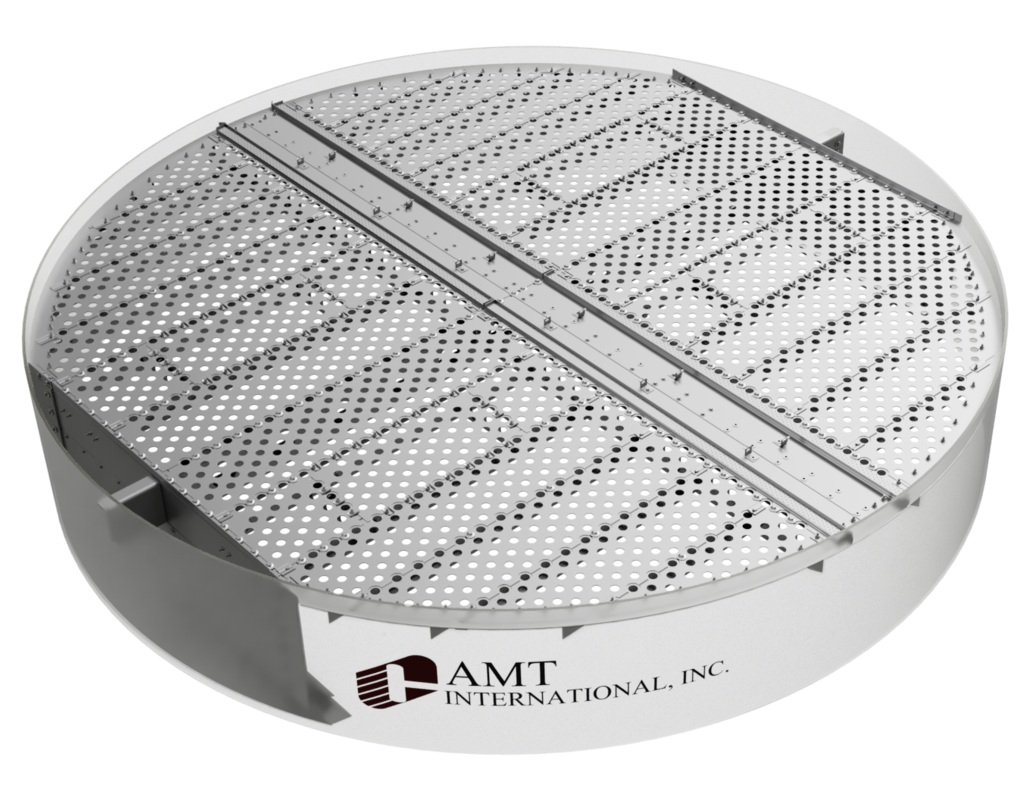

ADV® Pinnacle HIGH Performance Trays

Worldwide, ADV® Pinnacle High Performance Trays have been installed in over five thousand columns that range in inner diameter from 28" to 402" [760 mm to 10200 mm].

Many versions of ADV [Floating] Valves or ADVF [Fixed] Valves are utilized based on process requirements to meet a range of design conditions. Trays can be made of materials including, but not limited to, SS-410S, SS-316, Titanium, Monel, Hastelloy, etc. as required.

Retrofitting existing trays with AMT's patented high performance trays have been field proven to yield up to a 40% increase in throughput at comparable unit energy cost. Likewise, equipping new grass-roots towers with AMT ADV trays may allow over 20% higher capacity or up to 17% energy savings compared the industry standard tray design. The high performance ADV valve has been successfully operational in one pass trays, two pass trays, three pass trays, four pass trays, six pass trays, multi-pass trays (multi-downcomer trays), cartridge trays, and CD (Catalytic Distillation) trays

The larger the fractionation column or distillation column diameter, the greater the advantages of the AMT ADV trays in terms of initial equipment cost, speedy field installation, ease of maintenance, and operating energy savings. However it should be noted ADV cartridge trays have been successfully installed and are operational in columns as small as 20” [500mm].

ADV® VALVE TRAY Advantages

AMT ADV Pinnacle Performance Trays consist of a combination of various design features outlined below that allow for greater tray performance compared to the industry standard design. This in combination with our decades of design expertise allows us to achieve the highest tray performance possible (i.e., capacity, efficiency, pressure drop, turn-down and run-time) for your application. When compared with typical conventional valve or sieve trays, AMT ADV Pinnacle Performance Trays offer:

Up to 40% greater throughput capacity

Up to 15% better fractionation efficiency

Up to 20% lower pressure drop

Greater turn-down ratio

Resistant to fouling and longer column run time

Minimum modification for debottlenecking

Easier field installation of trays (No Welding Optional for Turn-Around)

Quick return on investment of de-bottlenecking cost

ADV® TRAY patented DESIGN FEATURE details -

advanced dispersion valves (ADV®)

Canopies are located on top of the Advanced Dispersion Valves. These create additional vapor outlets, which leads to uniform micro-dispersion of vapor for improved vapor-liquid contact.

The canopies also act as directional flow promotion devices, which help eliminate stagnant liquid pools and promote uniform liquid plug flow and froth densities across the entire active area.

With this feature, most fouling materials that would settle on the tray deck with standard trays are eliminated, leading to extended column run time.

QUICK-CONNECT ACTIVE JOINTS

Industry standard tray panels are connected with bolted joints which results in approximately 3” to 4” (75 mm to 100 mm) of inactive zones between every tray panel, reducing the possible active area on the tray.

These typical inactive zones on the tray decks allow liquid to by-pass (i.e., no contact with vapor) and also allow any fouling material to settle and build-up on the tray (due to no vapor/liquid contacting action).

AMT ADV Trays are designed with AMT’s patented Quick-Connect Active Tray Joints, which allows easy installation while also eliminating the inactive tray joints found in all other trays. As a result, the Quick-Connect Active Tray Joints:

Allow more effective and evenly distributed active area for vapor/liquid contact to increase tray capacity

Eliminate liquid by-pass for better tray efficiency

Eliminate inactive zones between tray joints to avoid any fouling material settling on the tray decks (extending the column run-time)

Reduce typical tray installation time by 30-50%

Quick Installation Active Joint

Higher Capacity and Flexibility

INLET BUBBLE PROMOTERS

The AMT ADV Pinnacle Performance Tray is designed with unique inlet bubble promoters to allow for froth initiation near the inlet area of the active panels. The froth initiation helps minimize the liquid gradient on the tray and promotes uniform froth distribution across the entire tray active area.

This results in higher tray capacity and operating flexibility. AMT offers a wide range of proprietary bubble promoter configurations that maximize the beneficial effects for any application.

CUSTOM DOWNCOMER DESIGNS

The downcomer design is an integral part of an optimized and balanced tray. Several downcomer designs, including our patented Downcomer Distributor technology, are available for all AMT trays.

With AMT's comprehensive knowledge and real world experience in how each downcomer type performs, AMT is able to fine tune tray performance to match your application.

Maximized Efficiency

AMT EADV De-Entrainment Trays

DE-ENTRAINMENT DEVICEs

AMT’s EADV Tray is the combination of our field proven ADV ® Pinnacle Performance Tray and AMT’s innovative De-Entrainment Device technology. EADV Trays can provide all the benefits of the ADV ® Tray while minimizing entrainment to maximize operating capacity. The de-entrainment device intercepts liquid spray that would otherwise bypass each tray. Liquid then falls as heavier droplets backwards to the active area of the tray below for enhanced vapor and liquid contact.

AMT’s Specialized De-Entrainment Devices can be applied to almost any tray type and is currently operational in columns all around the world.

Minimize Liquid Entrainment

10%-20% Additional Hydraulic Capacity

High Efficiency Design

Applicable to Numerous Tray Types

Available with Any Downcomer Design

MODERNIZATION (REVAMP)

For a typical plant modernization (revamp) project, the typical throughput is increased by 30% and the project can be carried out during the scheduled maintenance turn-around, which is normally 2 months or less. Expedited installation time frames can be facilitated by using our experienced field installation supervisors and engineers.

the AMT ADV® Pinnacle Performance Trays allows:

Reuse of all existing fractionation columns

No need to enlarge inlet vapor nozzles

No need for new foundation work or reinforcement

No costly and time-consuming replacement of larger columns as in past practices

Quick return on investment of the new mass transfer equipment, usually within one year

Significant improvement to column performance

When to contact AMT:

When your process licencors inform you you need to replace existing columns

When the experts inform you to enlarge the inlet vapor nozzles

When you are told you have to have new foundation work or reinforcement

When you are being sold mass transfer equipment (conventional valve or sieve trays) designed in the 90’s or even 50’s

When they tell you to hire an army of installers

AMT HAS YOUR SOLUTION

Though AMT recommends that process licensors and plant owners adapt the high performance AMT ADV Pinnacle Performance Trays for new plant construction or current process plant modernization (revamp).

AMT can design and fabricate almost any conventional tray optimized with ADV tray features to fit your needs. If high capacity is required, we provide our ADV - MP High Capacity Trays that can increase existing or revamped column capacity and performance significantly.

With all of the added advantages it just makes sense to incorporate the state of the art AMT ADV Pinnacle Performance Tray and the included features instead of the antiquated conventional trays for nearly all applications; The lower initial equipment cost, speedy field installation, ease of maintenance, greater operating energy savings, and our expert support provides greater return on investment and higher performance than the leading competitors.

You can count on AMT for a solid second opinion, we are just an email or phone call away: